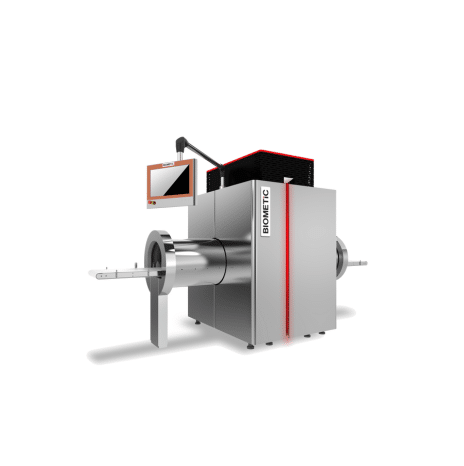

Xr scanner - Tomograph Mito

BIOMETiC

Contact a technical expert | Dowload the datasheet

The solution to guarantee complete food safety and quality

3D X-ray inspection system for food safety and quality

Advantages

- First and only 3D scanner on the market

- The Mito tomograph optimizes your production line upstream and downstream processes

- Intuitive display and easy to use interface

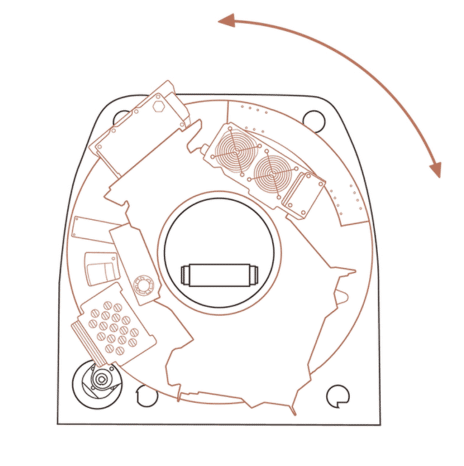

- Generates 3D images through a 360° scan using a gantry that rotates around the object

- Detects foreign objects with greater precision, regardless of their position and orientation

BIOMETiC Mito is a state-of-the-art food inspection system, incorporating advanced 3D X-ray technology coupled with artificial intelligence. It is capable of scanning products in real time, accurately capturing internal and external features to detect quality defects and foreign bodies. This system is the only one on the market to offer in-line 3D reconstruction, making it particularly effective in ensuring food safety. It is the only in-line CT scanner/tomograph available in the market

Mito’s patented computed tomography technology not only reduces errors and waste, but also protects consumer health and preserves brand reputation. Thanks to its great versatility, Mito can be customized to meet the specific needs of each company. What’s more, several models and configurations are available to suit different production requirements: model Mito C – Mito M – Mito B, each one with different specifications.

MITO C

- Computed tomography (3D and X-ray)

- Field of view: 250 mm

- glass jars, glass bottles and cans

- Food safety (glass-in-glass, metals, plastics, etc.)

- Food quality (fill level, jar seal, presence of vacuum, etc.)

- Production process optimization

MITO M

- Computed tomography (3D and X-ray)

- Field of view: 250 or 500 mm

- Multipacks and generic packaging

- Food safety (metals, plastics, paste clusters, etc.)

- Food quality (product’s dimension and geometry., alveolation…)

- Production process optimization

MITO B

- Computed tomography (3D and X-ray)

- Field of view: 250 mm

- Bulk products

- Food safety (kernel fragments, stones, metals, etc.)

- Food quality (product integrity, shape, etc.)

- Production process optimization

- Bakery

- Canning

- Cheese and dairy products

- Confectionery and sweets

- Meat and fish

- Frozen products and ready meals

- Snacks

- …

Brochure

MITO (pdf / 882,89 KB)