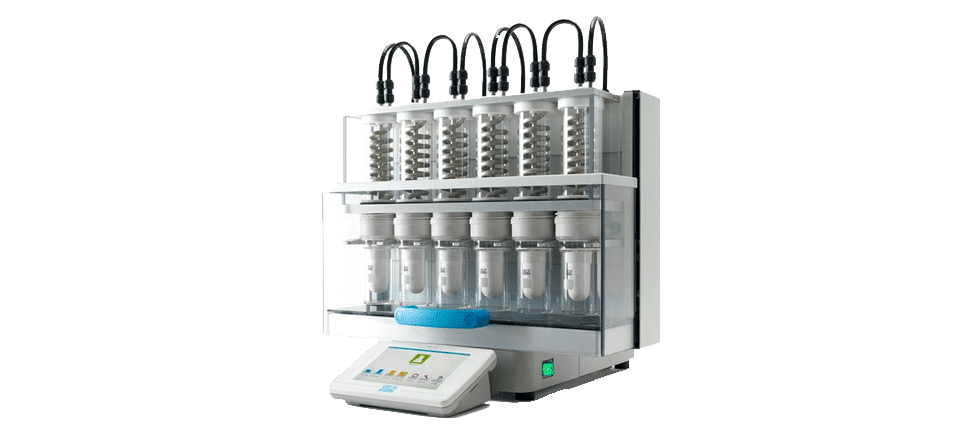

OXITEST Oxidation Stability Reactor

Velp

Oxidative Stability Studies Directly on the Whole Sample According to AOCS Standard Procedure

Innovative accelerated oxidation test for the determination of the oxidation stability of fats on the whole sample according to AOCS Cd-12c-16.

Advantages

- Quality control of raw materials and ingredients

- Transportation and effects on goods

- Storage period studies

- Product Development and behavior

- Formula Optimization

- Ingredient and alternative ingredients testing

- Process optimization

- Packaging study and alternative packaging comparison

Representative results testing the whole sample

The OXITEST reactor subjects the sample to a high oxidative stress environment in order to evaluate, in a short period of time, the resistance to fat oxidation:

- Established over-pressure of pure oxygen (6 bar, degree 5.0)

- High constant temperature, 90 °C

With the OXITEST Method, the stability test is performed directly on the sample as it is solid, liquid or doughy.

The method’s key advantage is that the OXITEST ensures representative results without extensive sample preparation.

Other components of the sample matrix such as chemical oxidants or transition metal can promote oxidation and the use of extracted matter may not be a suitable predictor of stability.

OXISoft™ software powerful and intuitive

The OXITEST is entirely controlled via PC through the intuitive OXISoftTM software which is able to control up to 4 OXITEST simultaneously and independently. The OXISoft™ is quick and easy-to-use, at a glance you always have the program parameters, work conditions and results.

The software comes with multi-lingual support and a pre-installed library of methods related to a wide range of sample types, you can use these, modify them and create your own methods!

Data management, reportiing and archive with the following test types:

- Repeatability test

- Freshness test

- Formulas comparison

- Packaging comparison

- IP during ageing

- Estimated shelf life

The Induction Period IP

The results of the OXITEST are expressed through the IP Induction Period.

The IP is the time required to reach the starting point of oxidation, corresponding to either a level of detectable rancidity or a sudden change in the rate of oxidation.

The longer the Induction Period, the higher the stability against oxidation over time.

OXIDATION CHAMBERS: 2

POWER: 900 W

WEIGHT: 16.5 kg

INTERFACE: USB

CAPACITY OF CHAMBERS: up to 100 ml each

DIMENSIONS (LxHxD): 365x190x485 mm