MarqMetrix Process Raman Analyzer

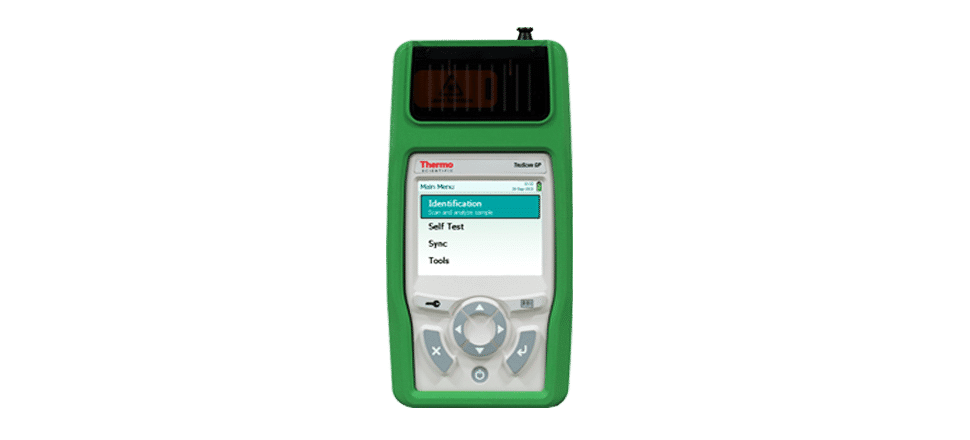

Thermo Fischer

Experience real-time, non-destructive analysis without the need for sample preparation.

The MarqMetrix All-In-One Process Raman Analyzer enables businesses to perform precise and immediate measurements, streamlining process monitoring across various industries.

Advantages

- Analysis without sample preparation to deliver Raman spectral results in real time

- Easy to set up and deploy by non-Raman spectroscopists

- Non-destructive to protect precious samples

- Non-invasive to minimize contamination of samples

- Small footprint for convenient deployment

- Factory calibration for hardware stability and portability

This compact analyzer delivers accurate, real-time Raman spectral results without requiring sample preparation, preserving valuable samples and minimizing contamination risks. Its user-friendly design allows even non-specialists to set up and operate the system effortlessly, integrating seamlessly into existing workflows. Factory calibration ensures consistent hardware stability and portability, facilitating timely optimization decisions.

| Feature | Details |

|---|---|

| Dimensions (W x D x H) | 25 cm x 25 cm x 7.7 cm |

| Operating Temperature Range | 15°C to 33°C |

| Laser Specifications | Excitation Wavelength: 785 nm; Power: 10 to 450 mW |

| Spectral Resolution | Average of 6.5 cm⁻¹ across the spectral range |

| Spectral Range | 100 to 3250 cm⁻¹ |

| Detector | Thermally stabilized CCD (2-stage TEC) |

| Optical Interface | FC/PC fiber optic connection |

| Electrical Requirements | 50/60 Hz |

| Dark Noise | ≤16.5 counts at 10-second integration |

| Ports | 1 RJ-45 Ethernet; 3 USB 3.0 |

| Software | MarqMetrix Raman Suite; Integrated PC (Windows 10) |

| Safety Features | Keyed laser interlock switch; Electronic laser trigger |

| Certifications | Class 3B laser device; FDA compliant |

| Included Accessories | Wireless mouse; HDMI cable; Monitor |

Bioproduction: Real-time monitoring of critical parameters in biopharmaceutical processes.

Oil & Gas Production: Analysis of refined fuels and carbon capture processes.

Industrial Fermentation: Process control in cultivated meat production.

Polymers: Characterization and quality control of polymer materials.